The mining industry frequently involves the handling and transport of heavy materials and equipment in complex environments. Mining professionals face significant challenges such as unpredictable terrain, high-altitude lifts, and stringent safety protocols. Downtime caused by inefficient or unsafe lifting tools can drastically affect productivity, leading to substantial operational costs.

Mining operators require lifting solutions that not only handle heavy loads securely but also adapt to diverse site conditions while minimizing risk to personnel and equipment.

Traditional mining lifting tools, often fabricated from standard steel alloys, tend to be bulky, heavy, and single-purpose. These characteristics limit their maneuverability for high-altitude operations and reduce precision during load release.

Common drawbacks include:

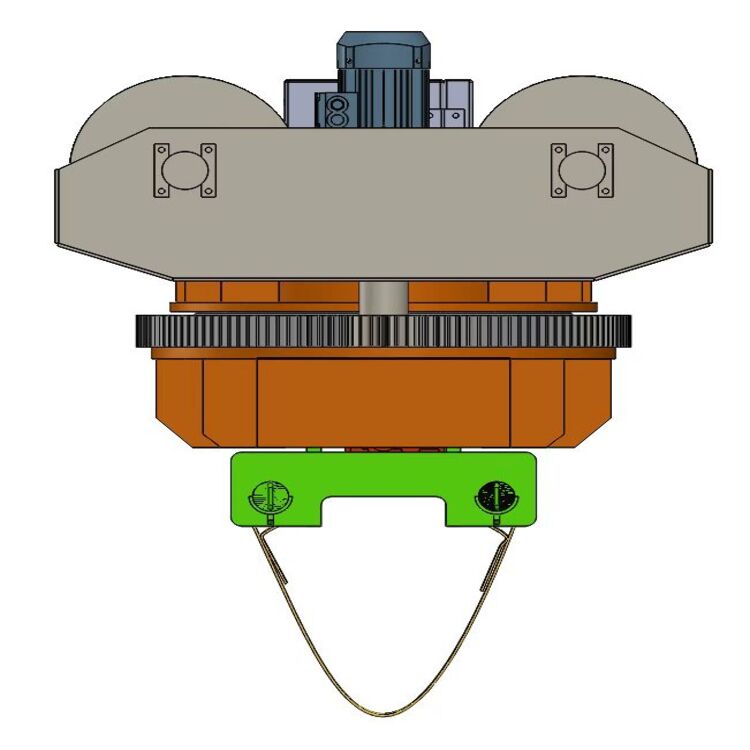

Emerging multi-functional high-altitude load release beams are revolutionizing lifting operations in mining. These advanced tools leverage high-strength, lightweight alloy materials that significantly reduce tool weight—often by up to 30% compared to traditional steel counterparts—without sacrificing durability or load capacity.

Key features include:

| Feature | Benefit |

|---|---|

| Lightweight High-Strength Alloy | Enhances maneuverability, reduces crane stress |

| Integrated High-Altitude Release Mechanism | Enables precise and remote load release, minimizing risk |

| Multi-Functional Adaptability | Suitable for various load dimensions and site scenarios |

| Enhanced Safety Features | Reduces operator exposure and incident rates |

The implementation of these tools has been shown to improve safety records by up to 25% and increase operational efficiency by 15-20%, according to industry pilot reports.

A copper mining operation in South America piloted the multi-functional load release beam across varying terrain and multi-story shafts. The results exhibited a tangible reduction in downtime, with load release times shortened by 35%, and zero safety incidents related to load drops during a six-month evaluation period.

Additionally, operators commended the tool's ergonomic design, which lowered physical strain and simplified training requirements, ultimately contributing to sustained productivity gains.

| Criteria | Traditional Tools | Multi-Functional Release Beams |

|---|---|---|

| Material | Steel (Heavy, prone to corrosion) | Lightweight Alloy (Corrosion-resistant) |

| Weight Reduction | N/A | Up to 30% |

| Load Release Mechanism | Manual, limited precision | Remote-controlled, high precision |

| Safety Level | Lower, higher risk of accidents | Enhanced, built-in fail-safes |

| Operational Efficiency | Baseline | Increases productivity by 15-20% |

Mining operators and supply chain managers: what are your primary challenges with heavy load handling? Have you trialed multi-functional lifting devices, and what impact did you observe on safety and productivity? Share your insights and experiences to help the industry evolve toward safer, more efficient operations.

Discover How to Boost Mining Safety & Efficiency with Advanced Load Release Beams