In today's rapidly evolving logistics and port operations landscape, handling diverse container dimensions with precision and safety remains a cornerstone challenge. Titan Ding Heavy Industry’s self-developed custom container lifting gear seamlessly combines innovative engineering with robust durability, offering solutions tailored to meet the high-demand expectations of global freight handlers.

Container sizes and weights vary widely—commonly ranging from 20-foot (approximately 6 meters) to 40-foot and specialized oversized units exceeding 30 tons. Selecting appropriate lifting equipment demands a deep understanding of load distribution, structural integrity, and operational ergonomics. Titan Ding’s range provides equipment with lifting capacities from up to 50 tons, ensuring compatibility with multiple container types while maintaining minimal downtime and maximum safety margins.

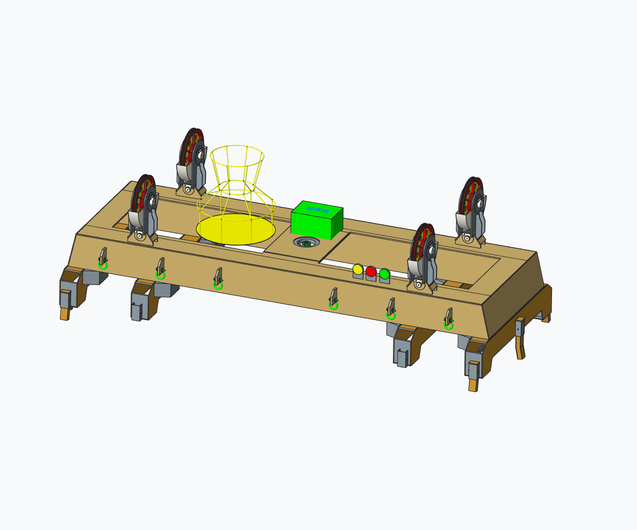

Critical to the performance is the gear’s flexible design—adjustable spreaders, reinforced steel frames, and modular components allow for swift adaptation across container dimensions and weights, optimizing throughput in port and railway terminal operations.

| Parameter | Specification Range | Application Focus |

|---|---|---|

| Lifting Capacity | 10 to 50 tons | Standard & oversized containers |

| Spread Adjustment | 4.8m to 12.2m | Adaptable container widths |

| Material | High-strength alloy steel | Enhanced durability & corrosion resistance |

Safety incidents in container handling often stem from equipment inadequacies or poor adaptability. Titan Ding Heavy Industry addresses these challenges with rigorous engineering controls embedded into every product—such as integrated overload indicators, precision locking mechanisms, and anti-sway damping systems. These features not only protect operators and cargo but also expedite cargo turnarounds, reducing idle times by an average of 15% based on client deployment feedback.

The modular construction supports easy field maintenance, critical for minimizing operational interruptions. Components are designed for quick replacement without disassembling entire gear assemblies, streamlining upkeep workflows and extending lifecycle durability to exceed 10 years under typical port operation stresses.

A major European railway logistics operator reported a consistent 20% throughput increase after integrating Titan Ding’s custom lifting gear into multimodal handling nodes. Enhanced adaptability allowed smoother transitions between maritime unloading and inland rail carriage, drastically lowering container dwell time.

Similarly, a freight forwarder in Southeast Asia leveraged these lifting solutions in dense port environments, reducing equipment-related delays by nearly 25%, thus securing competitive advantage in a market where turnaround time critically influences service contracts.

Businesses seeking to deploy or upgrade container handling systems must consider operational environment, container type frequency, and throughput goals. Titan Ding offers expert consultancy to customize equipment configurations, ensuring the best match between technical capabilities and logistic workflows.

Regular preventative maintenance is advised—commonly scheduled every 1,000 operational hours or quarterly—focusing on hydraulic system integrity, structural wear points, and safety sensor calibrations. This disciplined approach has been demonstrated to reduce unplanned downtime by up to 18%.

Titan Ding Heavy Industry stands out in the global logistics equipment sector by continuously integrating cutting-edge materials science and adaptive design philosophies. Their commitment to solving complex cargo handling challenges through customized, robust, and intelligent lifting gear solutions cements their leadership status while empowering clients to elevate operational capacity sustainably.

Discover How Titan Ding’s Custom Container Lifting Gear Can Transform Your Logistics Today