In critical industries such as bearing manufacturing, forging, and power generation, lifting operations involving bearing rings demand utmost precision, strength, and safety. Selecting the right lifting tool directly impacts operational reliability and workplace protection.

High-strength alloy steel forms the backbone of advanced bearing ring lifting tools, offering unmatched load-bearing capacity and wear resistance. Materials engineered with alloy steel withstand stresses far beyond conventional steel tools, ensuring stability during heavy-duty lifting tasks.

The enhanced mechanical properties reduce risks of deformation and fatigue failure, which are crucial when handling components weighing several tons. A typical alloy steel lifting tool delivers a tensile strength exceeding 1,200 MPa, surpassing traditional mild steel by over 50%, thus securing bearings during transit and installation.

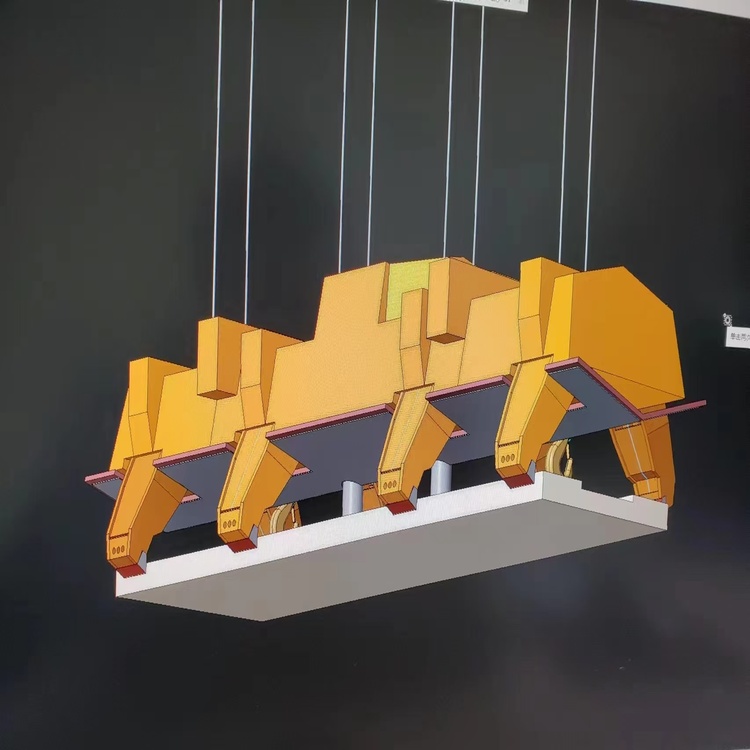

A unique clamping design integrated into these tools prevents slippage and deformation of bearing rings. This mechanism adapts dynamically to various ring sizes and shapes, locking securely without damaging the component surfaces.

Such precision control is vital in industries like nuclear power and aerospace where millimeter-level accuracy is a must. The secure grip also reduces downtime by minimizing repositioning, which typically accounts for up to 15% of total operation time.

These lifting tools demonstrate versatility across sectors:

| Industry | Application | Benefits |

|---|---|---|

| Bearing Manufacturing | Handling heavy bearing rings during assembly | Improved safety, reduced handling errors |

| Forging Plants | Transporting hot and heavy metal rings | Heat-resistant, durable under extreme conditions |

| Power Industry | Precise lifting in power plant installations | Alignment accuracy, compliance with safety standards |

| Automotive Assembly | Facilitating fast, safe movement of bearing components | Boosted throughput, reduced workplace incidents |

The design philosophy behind these lifting tools prioritizes adaptability. Their compact form factor fits a broad spectrum of bearing dimensions and operational contexts, from confined factory floors to vast construction sites.

Adjustable clamping ranges can accommodate diameters typically between 150 mm to 1,200 mm, making them effective for diverse project requirements without needing multiple tool sets. This flexibility reduces capital expenditure and simplifies inventory management for industrial operators.

Compliance with international standards such as ISO 9001 and API 8C underlines the reliability of these tools. The rigorous testing procedures and robust structural design ensure operators can trust the equipment to perform consistently under pressure.

Ergonomic considerations are embedded into tool construction, with intuitive controls and easy-to-maintain surfaces that resist corrosion and abrasion. This results in reduced training time, fewer operational errors, and enhanced long-term value.

Choosing the right alloy steel bearing ring lifting tool means upgrading your operational safety and efficiency. Equip your team with technology engineered for durability, flexibility, and uncompromising security.