Efficient container handling is the backbone of global port and logistics operations. Dalian Taiding Heavy Industry, leveraging over a decade of technological innovation, has developed state-of-the-art container lifting devices tailored for diverse environments such as ports, warehouses, and rail terminals. This article delves into the structural design characteristics and load capacities of these lifting attachments, offering scientifically grounded selection guidelines and workflow optimizations that enhance safety and productivity.

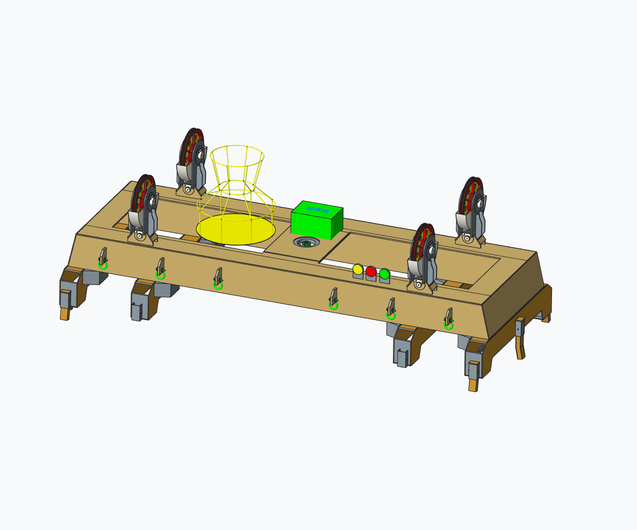

The core of Dalian Taiding’s lifting equipment lies in robust structural design engineered to accommodate a wide range of container sizes — from 20ft to 40ft ISO standard boxes — with maximum payloads up to 40 metric tons. Utilizing high-tensile steel and reinforced joints, the equipment exhibits superior durability under heavy-duty cycles, minimizing deformation risks.

Key structural elements include replaceable lifting beams, swivel hooks, and safety locking mechanisms. The attachments support dynamic loads up to 120% of their rated capacity, verified through rigorous finite element analysis (FEA) and certified by international standards such as ISO 10855-2.

Different handling environments impose unique demands on lifting devices. For example:

| Scenario | Key Requirements | Recommended Features |

|---|---|---|

| Port Operations | High throughput, heavy payloads, space constraints | Compact design, quick-connect hooks, anti-sway devices |

| Warehouse Storage | Precision placement, moderate load cycles | Adjustable width beams, fine positioning controls |

| Railway Transport | Intermodal compatibility, shock absorption | Shock mounts, reinforced joints, standardized fittings |

By tailoring lifting gear parameters—such as beam length, hook type, and control system—to these demands, logistics operators can reduce cycle times by up to 15% and extend equipment lifespan by 20%.

An international freight-forwarding company reported a 25% reduction in loading times after integrating Taiding’s custom lifting attachments into their port-side operations. Particularly notable was the improvement in safety metrics, with near-zero incidents in the six months following deployment.

Similarly, a railway logistics firm achieved streamlined container transfers between railcars and warehouses, increasing throughput by 18% and cutting maintenance downtime by 12% through equipment optimizations focused on shock-absorption and modular components.

Recognizing the diverse operational requirements across logistics fields, Taiding Heavy Industry offers tailored customization services—ranging from modular beam adjustments to sensor-integrated control systems that enable real-time monitoring of load stress and operating conditions.

Preventative maintenance programs are recommended to maintain optimal performance. Scheduled inspections every 1,000 operational hours, coupled with component replacement guidelines, ensure consistent safety and efficiency, minimizing unexpected downtime and repair costs.

Emerging demands in green logistics and automation have prompted Taiding to integrate energy-efficient hydraulics and IoT-enabled predictive maintenance features in their latest generation of container lifting equipment. Customer feedback underscores the premium placed on equipment safety and adaptability, with 93% of surveyed clients citing improved operational reliability post-upgrade.

Ready to elevate your logistics efficiency with equipment that is highly durable, safe, and designed for your unique application? Discover Taiding Heavy Industry Solutions Today