In today’s fast-paced global trade environment, port and terminal operators face mounting pressure to enhance operational efficiency without compromising safety. Central to this challenge is the effective selection and optimization of container lifting equipment. This article explores key strategies for optimizing port logistics machinery—particularly focusing on container spreaders and cranes—addressing lifting capacity, structural design, and process improvements that collectively boost productivity. Leveraging Tianding Heavy Industry’s innovations in high-performance container handling technology and real-world applications, professionals gain actionable insights for smarter equipment deployment and workflow enhancement across diverse logistics scenarios.

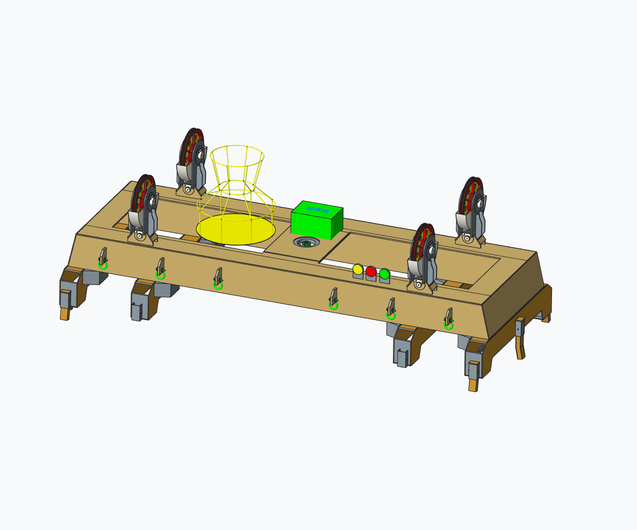

Container spreaders are critical components in port logistics, responsible for safely engaging, lifting, and transferring containers ranging from 20 to 40 feet and beyond. The lifting capacity of spreaders generally spans from 20 to 65 tons, calibrated based on container weight, safety margins, and operational demands. Tianding Heavy Industry's proprietary designs incorporate tensile steel alloys and reinforced frame structures that reliably support rated loads with enhanced durability and fatigue resistance.

| Model | Max Lifting Capacity (tons) | Weight (kg) | Compatibility |

|---|---|---|---|

| TD-S-30 | 30 | 950 | 20~40ft Containers |

| TD-S-50 | 50 | 1,375 | Up to 45ft Containers |

Beyond capacity, the structural design of the lifting equipment plays a pivotal role. Advanced features such as telescoping spreader beams allow for side-shifting and twisting motions, facilitating precise container positioning. Tianding integrates extendable beam mechanisms combined with rotational joints, optimizing vertical and horizontal load distribution and improving maneuverability during complex stacking or loading tasks.

Operational bottlenecks often arise from mismatched equipment and workflow inefficiencies. Container lifting operations can witness an average downtime of 12-15% due to equipment failure or suboptimal configurations. Strategic equipment selection—tailored to container size variability and weight profiles—can reduce cycle times by up to 20%, substantially elevating terminal throughput.

Tianding Heavy Industry’s product line emphasizes modularity and quick adaptation. For example, spreaders with adjustable lifting hooks and automated locking systems accommodate various container sizes with minimal manual intervention. Incorporating sensors that report real-time load data and operational status helps preempt mechanical failures, enabling predictive maintenance—a critical factor in minimizing unscheduled downtime.

A leading rail logistics operator recently integrated Tianding’s container spreaders within a multimodal transfer hub, serving intermodal container shipments between ports and inland terminals. Post-deployment data showed a 15% reduction in container dwell time and a 10% increase in crane operational availability over six months. Enhanced equipment reliability and configurable spreader adjustments allowed seamless transitions between rail wagon heights and truck bed levels, optimizing the transfer cadence.

This case illustrates how technical excellence combined with intelligent operational design can deliver measurable productivity gains. Furthermore, comprehensive maintenance guidelines issued by Tianding focus on corrosion resistance treatments and hydraulic system calibration, which serve to extend equipment lifecycle by an estimated 25%.

Safety compliance is non-negotiable in port logistics, where equipment failures risk costly accidents and operational halts. Tianding provides tailored maintenance schedules emphasizing:

Leveraging IoT-based condition monitoring via integrated sensors allows predictive alerts up to 48 hours before potential failure events, facilitating proactive downtime management. This approach not only upholds stringent safety standards but also improves asset utilization rates—critical in high-traffic ports.

The port logistics sector is rapidly evolving with digitalization and environmental sustainability shaping equipment innovation. Key trends include:

Tianding Heavy Industry continually invests in R&D to stay at the forefront of these trends, releasing next-generation spreaders equipped with smart control systems and eco-friendly materials.

With decades of engineering expertise and a track record of client success, Tianding Heavy Industry stands out as a trusted partner for port logistics equipment solutions. Their blend of innovative technology, robust design, and dedicated after-sales support empowers logistics operators to optimize efficiency, enhance safety, and future-proof their operations.

Unlock Superior Port Logistics Efficiency with Tianding’s Advanced Container Handling Solutions