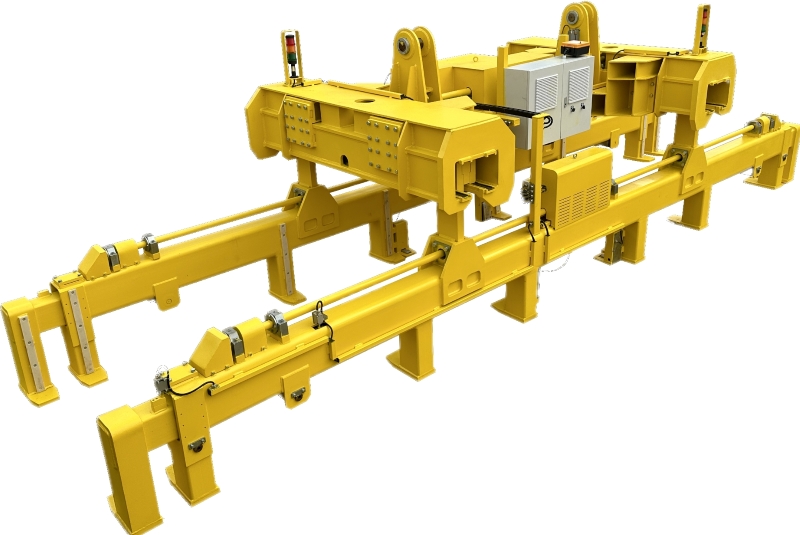

Across the manufacturing, warehousing, port logistics, and construction sectors, demanding material handling challenges call for equipment that delivers both power and precision. High-strength panel stacking tools have emerged as pivotal devices to optimize the loading, unloading, and transportation of heavy panels. Engineered with safety, durability, and operational efficiency in mind, these tools are rapidly becoming a cornerstone for enterprises aiming to streamline workflow and safeguard assets.

Developed to withstand substantial loads while guaranteeing a secure grip, high-strength panel stacking equipment integrates advanced clamping systems and versatile drive options including hydraulic, electric, and manual actuation. With load capacities often exceeding 1500 kilograms per clamp, these tools ensure safe lifting and minimize panel damage, crucial for sensitive or expensive materials.

Safety mechanisms, such as automatic locking during suspension and overload protection, complement the robust mechanical framework. The lightweight yet rugged construction uses high-grade steel alloys, balancing ease of maneuverability with longevity and low maintenance costs.

Various industries reap measurable benefits from deploying high-strength panel stacking tools. In manufacturing plants, these tools reduce manual handling injuries by up to 60% and accelerate loading cycles by approximately 30%. Warehousing operations report a reduction in product damage incidents by 25%, while port logistics companies streamline container loading, improving turnaround times by 20%.

| Industry | Key Benefit | Efficiency Improvement |

|---|---|---|

| Manufacturing | Reduced manual labor & injury risks | +30% speed of panel handling |

| Warehousing | Minimized product damage | -25% damage rates |

| Port & Logistics | Faster container loading cycles | +20% turnaround efficiency |

| Construction | Improved site material handling safety | Lower accident rates by ~40% |

Unlike conventional panel handlers relying on clamps with limited load ranges or pneumatic systems prone to leaks, this latest generation of stacking tools employs a hybrid clamping technology ensuring stable grip under varying panel sizes and weights. The adaptability to various drive mechanisms allows customization per facility specifications and energy considerations.

Moreover, integrated smart sensors can optionally provide real-time load and safety data, aligning with Industry 4.0 initiatives that many leading companies are adopting for streamlined quality assurance.

As automation and intelligent systems reshape material handling worldwide, the high-strength panel stacking tool is designed to integrate seamlessly with automated guided vehicles (AGVs) and warehouse management systems (WMS). Predictive maintenance features embedded through IoT connectivity minimize downtime, while user-friendly interfaces reduce training overhead.

These innovations not only elevate handling precision and safety but also drive sustainability by reducing waste and optimizing labor deployment.

Interested in exploring how high-strength panel stacking tools can redefine your operational efficiency and safety standards? Our experts are ready to share tailored advice and detailed product data.