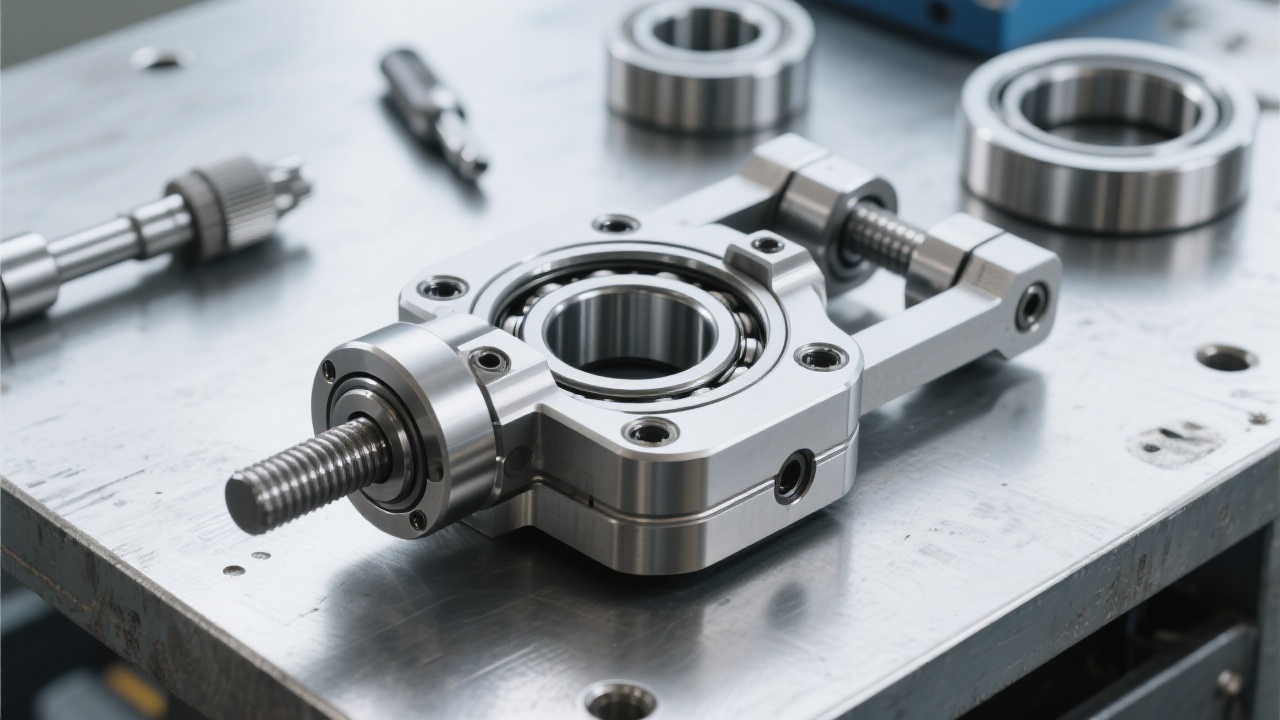

In industries where precision, safety, and operational efficiency form the backbone of manufacturing success, heavy-duty bearing ring lifting tools emerge as indispensable assets. Crafted from robust high-strength alloy steel and engineered with proprietary clamping mechanisms, these tools ensure unparalleled load-bearing capacity and steadfast stability throughout lifting operations. Their versatility spans critical sectors including bearing manufacturing, forging, power generation, construction equipment, and automotive production lines.

The backbone of any lifting tool's performance is the material quality. Heavy-duty bearing ring lifters are fabricated using premium high-strength alloy steels that deliver tensile strengths exceeding 1,200 MPa. This elevated mechanical property spectrum translates into superior resistance against deformation, fatigue, and corrosive environments commonly encountered in industrial workplaces. The careful metallurgical treatment further enhances toughness, ensuring durability under cyclic loading conditions inherent in heavy bearing operations.

A defining feature separating advanced lifting tools from generic alternatives is the patented clamping system. This system guarantees secure gripping on bearing rings, eliminating slip risks that could compromise personnel safety and component integrity. The mechanism dynamically adjusts to varying ring diameters from 250 mm to over 1000 mm, accommodating a vast range of industrial requirements without sacrificing operational steadiness.

The adoption of these lifting solutions spans multiple sectors:

| Industry | Application | Benefit Highlight |

|---|---|---|

| Bearing Manufacturing | Safe handling during forging and heat treatment processes | Enhanced operational safety, minimized downtimes |

| Forging Industry | Transporting hot rings with thermal endurance | Improved worker safety and process efficiency |

| Power and Heavy Equipment | Assembly and maintenance of large rotating machinery | Reliable lifting reduces equipment risk |

| Construction Machinery | Handling heavy bearing rings during on-site assembly | Streamlined workflow, higher safety compliance |

| Automotive Industry | Precision transport in automated production lines | Reduced operational hazards & quality assurance |

Users report that integrating these lifting tools into daily operations reduces heavy lifting injuries by over 40% and increases throughput by an average of 25%, underscoring their contribution to workplace safety and productivity enhancement.

Each industrial environment poses unique challenges — from high temperatures and heavy loads to limited access and repetitive handling. Heavy-duty bearing ring lifting tools incorporate adjustable gripping pressures, corrosion-resistant finishes, and ergonomic designs to mitigate operator fatigue and maximize safety margins. Compliance with international safety standards such as ISO 12100 and API ensures that these tools not only perform but do so within trusted regulatory frameworks.

Beyond robust construction, the manufacturers focus on user-centric aspects by providing comprehensive visual guides, operation videos, and interactive training modules. These resources shorten onboarding time by 30%, ensuring operators handle the equipment confidently and safely from day one.

Here's an example: Industrial plants incorporating video tutorials and QA sessions report doubled engagement in safety protocols and a 15% drop in lifting-related incidents within six months.

Have questions about integrating heavy-duty bearing ring lifting tools into your operations? Share your challenges or success stories below and connect with industry experts to optimize your safety and productivity.