Are you facing the problems of low efficiency and high safety risks in steel coil handling at port terminals? You're not alone. Many port operators are struggling with these issues, which stem from high risks, low efficiency, and a strong reliance on manual labor.

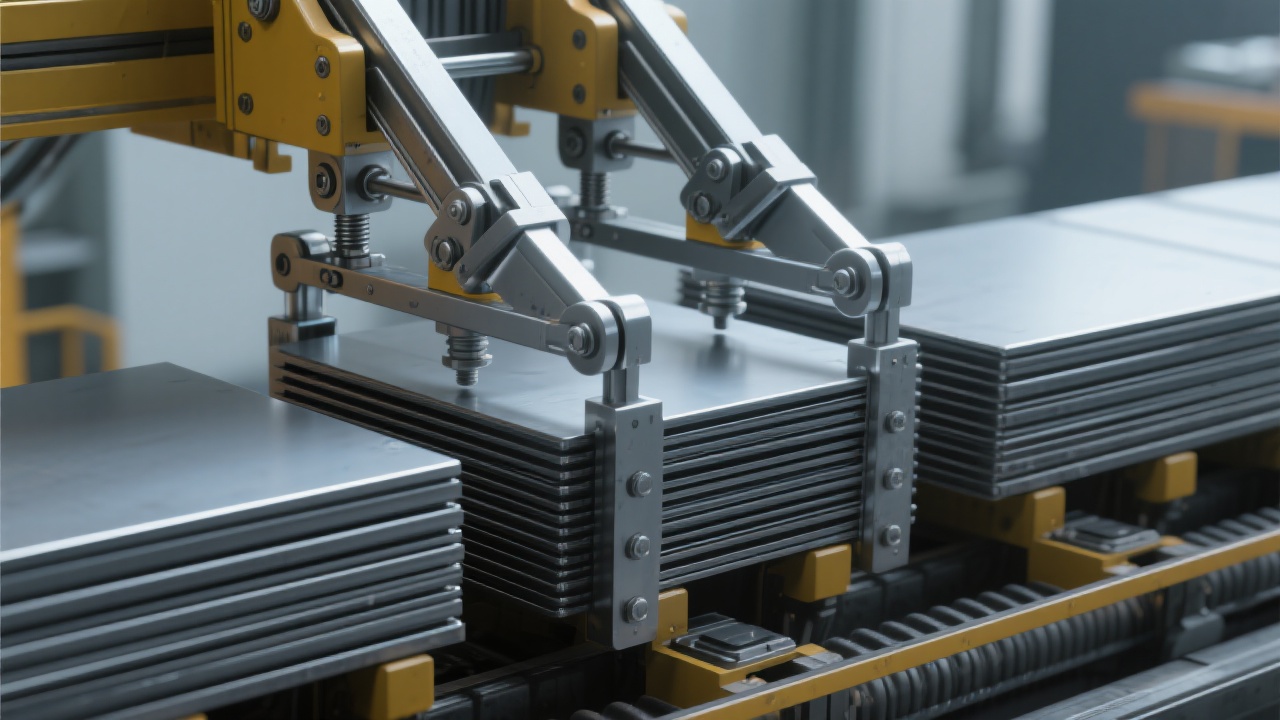

The high - efficiency steel coil lifting equipment is specifically designed for complex environments. It features high - strength materials, a compact design, a stable clamping mechanism, and multi - angle flipping capabilities. The use of high - strength materials ensures that the equipment can withstand the heavy load of steel coils, while the compact design allows it to operate in limited spaces at the port.

The stable clamping mechanism firmly holds the steel coils, preventing them from slipping during the lifting and flipping process. Moreover, its multi - angle flipping ability enables a smooth transition from vertical to horizontal positions, which is crucial for efficient handling at the port. All these features work together to reduce the need for manual intervention, thereby lowering labor costs and minimizing risks.

Let's take a look at a real - world example. A large port adopted this steel coil lifting equipment and witnessed remarkable improvements. After implementation, the port's steel coil handling efficiency increased by 40%, and the work - related injury rate decreased by 65%. These numbers clearly demonstrate the practical value of the equipment in enhancing both safety and efficiency. Imagine the peace of mind it brings to the workers, knowing that they are operating in a safer environment with reduced physical exertion.

When compared with traditional slings, it becomes evident why they are no longer suitable for modern port terminals. Traditional slings lack the advanced features of this new equipment. They are often bulky, difficult to operate in complex environments, and have limited capabilities in terms of flipping and positioning steel coils. As a result, they are less efficient and pose higher safety risks, especially when dealing with large - scale and heavy - duty steel coil handling.

The application of this steel coil lifting equipment is not limited to port terminals. It can also be used in steel mills and logistics centers, creating a full - chain handling solution. In steel mills, it can efficiently move steel coils from production lines to storage areas. In logistics centers, it helps in the quick and safe transfer of steel coils during the shipping process.

By using this equipment, companies can achieve seamless handling of steel coils throughout the entire supply chain, improving overall productivity and safety. It's a game - changer in the field of heavy - duty material handling.

Let every steel coil handling operation be more stable, faster, and safer. Say goodbye to the traditional cumbersome methods and embrace the new era of intelligent handling. Are you ready to transform your steel coil handling operations?

How does your terminal deal with the challenges of steel coil handling? Share your experiences and let's discuss how to further improve the safety and efficiency of steel coil handling.