Dalian Tiding Heavy Industry's independently developed container lifting equipment is a remarkable innovation in the logistics industry. The use of high - strength steel in the equipment is a key factor in enhancing its durability and load - bearing capacity. High - strength steel can withstand greater pressure and stress. For example, compared with ordinary steel, it can increase the load - bearing capacity of the equipment by about 30%.

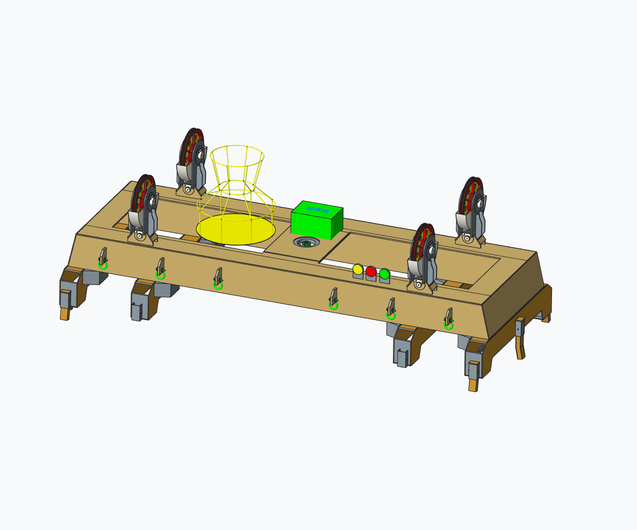

The unique structure design also plays a crucial role. The special structure can effectively disperse the load, reducing the risk of local damage. This design not only extends the service life of the equipment but also ensures stable operation during heavy - load operations.

The rotation crane structure and telescopic beam adjustment technology are the highlights of this container lifting equipment. The rotation crane structure allows the equipment to rotate 360 degrees, which greatly improves the flexibility of operation. It can easily reach different positions of the container, adapting to various working scenarios.

The telescopic beam adjustment technology enables the equipment to handle containers of different sizes. Whether it is a 20 - foot or 40 - foot container, the equipment can adjust the beam length according to the actual size, achieving seamless adaptation. This technology can increase the operation efficiency by about 25% compared with traditional equipment.

The precise locking and unlocking mechanism is of great significance for ensuring the safety of operations and reducing cargo damage. This mechanism uses advanced sensors and control systems to ensure accurate connection and disconnection with the container. During the operation, it can reduce the error rate to less than 1%, effectively preventing the container from falling or shifting, thus minimizing the risk of cargo damage.

In different scenarios such as ports, docks, warehouses, and logistics transportation, the equipment offers mechanical, pneumatic, and hydraulic drive modes. Each drive mode has its own characteristics and application scenarios.

| Drive Mode | Technical Features | Application Scenarios |

|---|---|---|

| Mechanical | Simple structure, easy maintenance | Small - scale warehouses with relatively stable operations |

| Pneumatic | Fast response, suitable for high - frequency operations | Ports with high - intensity operations |

| Hydraulic | High power, strong load - bearing capacity | Large - scale docks and logistics centers |

For operators and managers, proper maintenance and safety operation are essential. Regularly check the lubrication of the equipment, and replace the lubricating oil every 500 hours of operation. Check the integrity of the high - strength steel structure, and conduct a comprehensive inspection every 3 months. When operating, strictly follow the safety operation procedures, such as wearing safety helmets and safety belts.

In conclusion, Dalian Tiding Heavy Industry's container lifting equipment, with its advanced technology and excellent performance, can effectively improve the efficiency and safety of container handling operations. It helps the logistics industry achieve efficient and safe upgrades, extends the service life of equipment, and enhances the overall productivity of the industry. If you want to learn more about this high - performance container lifting equipment, click here.