The automotive manufacturing industry constantly strives to balance increased production efficiency with stringent safety standards. One innovative solution gaining traction is the use of multi-functional lifting devices in production and maintenance lines. These tools not only streamline workflows but also considerably reduce labor-related risks, bolstering both output and workplace safety.

Amid rising consumer demand and rapid technological advancement, automotive production lines face significant pressure to optimize resources and reduce downtime. Manual handling of heavy automotive components contributes to increased injury rates, with studies showing that lifting-related incidents account for nearly 35% of workplace injuries within manufacturing environments. This underscores the urgent need for reliable equipment that minimizes human exertion while maintaining precision.

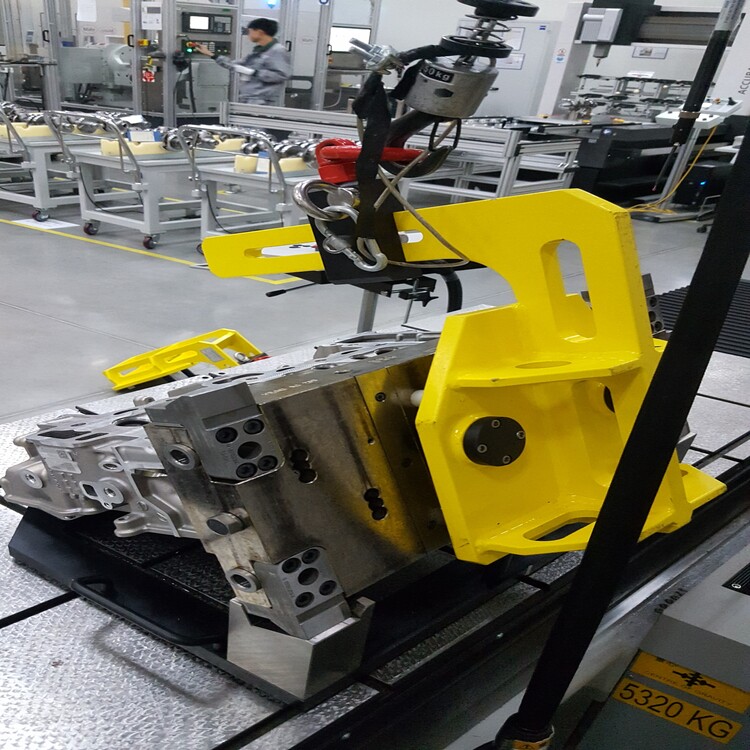

The core strength of these lifting tools lies in their application of high-strength lightweight materials such as aerospace-grade aluminum alloys combined with reinforced polymer composites. This construction yields a favorable strength-to-weight ratio, reducing operator fatigue without compromising load capacity—typically rated for up to 500 kilograms.

A patented clamping mechanism offers secure grip adaptability, accommodating diverse automotive components ranging from engine blocks to chassis parts. The device's adjustable design enables fine calibration for varying payload shapes and sizes, facilitating streamlined integration across different production stages without necessitating multiple specialized rigs.

A leading European automotive supplier reported a 25% reduction in production downtime after integrating these lifting devices across their assembly lines. Concurrently, incident reports related to manual material handling decreased by 40% within six months post-deployment. This translated to faster throughput and enhanced worker morale, illustrating the tangible benefits of such technology.

Beyond assembly lines, these lifting devices have demonstrated versatility in repair workshops, where precise, safe handling of heavy components accelerates vehicle turnaround times. In warehouse environments, their use streamlines logistic flows by enabling secure stacking and transfer of bulky parts, mitigating damage risk and operator strain.

Additionally, these devices facilitate maintenance activities involving heavy machinery, contributing to comprehensive safety compliance and adherence to occupational standards such as ISO 45001.

| Key Feature | Benefit | Application Scenario |

|---|---|---|

| Lightweight yet Strong Materials | Reduces operator fatigue, increases maneuverability | Assembly, repair, storage handling |

| Adjustable Clamping Mechanism | Secures varied component shapes safely | Engine assembly, chassis mounting |

| Multi-scene Usability | One device serves multiple operations | Manufacturing, maintenance, warehousing |

Feedback from industry leaders further cements confidence in these lifters. One global OEM maintenance manager highlighted: "The integration of these lifting devices has transformed our safety culture and productivity metrics. Our teams now experience significantly less strain, with near elimination of lifting-related injuries."

Such endorsements reflect not just technical merits, but also a trustworthy partnership-oriented approach valued by clients worldwide.

As automotive production demands rise, integrating advanced lifting technology is a strategic imperative. These multi-functional lifting devices offer not only quantitative benefits in downtime reduction and accident mitigation but also play a pivotal role in modernizing workflows, enabling safer and more agile manufacturing ecosystems.