In the dynamic landscape of the automotive manufacturing and repair industry, efficiency and safety are paramount. However, many businesses in this sector are grappling with persistent issues such as low efficiency and high safety risks. Manual handling of heavy components like engines and gearboxes not only consumes a significant amount of time but also exposes workers to potential injuries. These challenges have a direct impact on production schedules, cost control, and overall workplace safety.

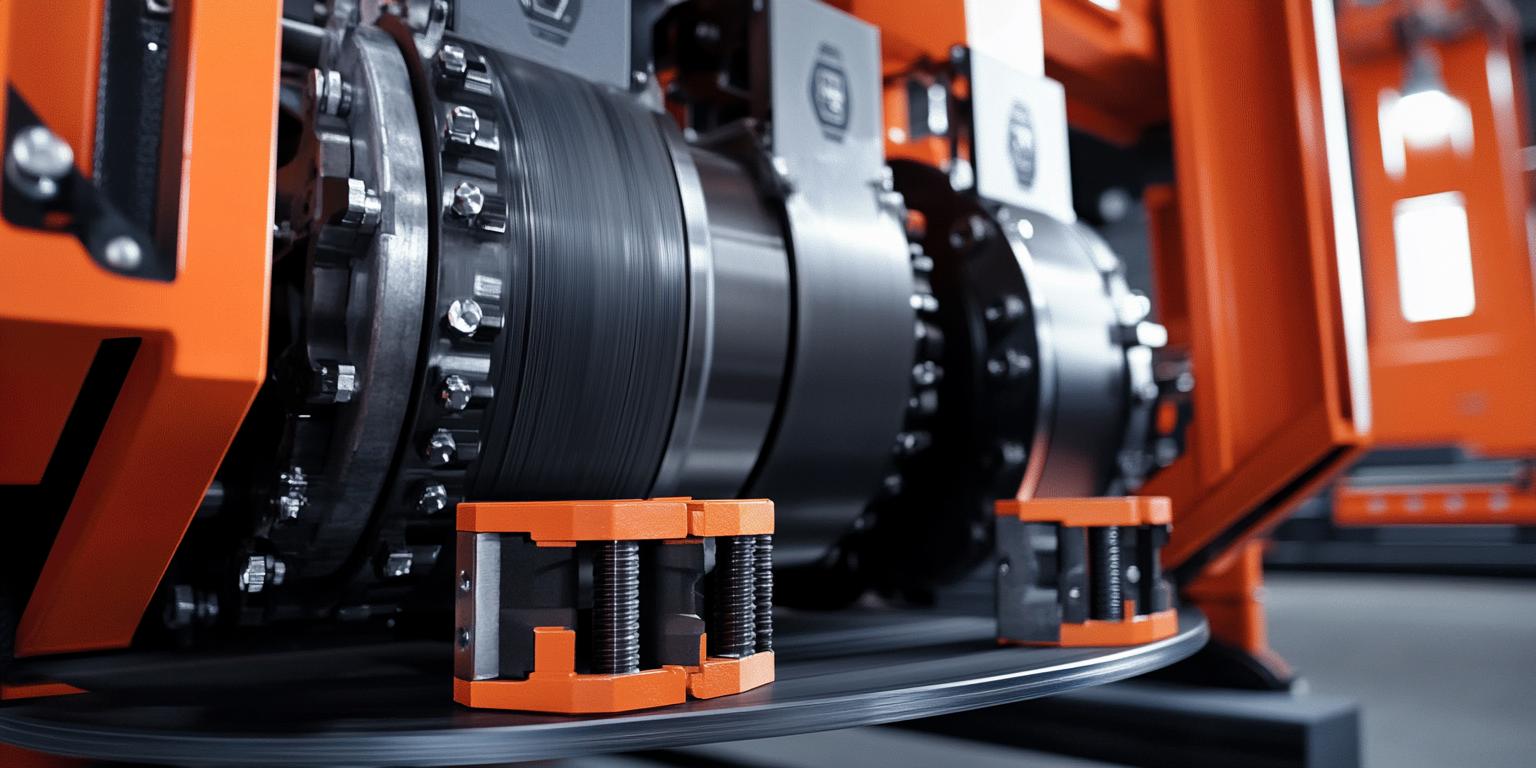

Enter the multifunctional automotive production line hoist, a revolutionary solution designed to address these long - standing problems. This hoist is crafted from high - strength, lightweight materials, which significantly reduce its own weight while maintaining excellent load - bearing capacity. The adjustable clamping mechanism allows it to securely grip components of various shapes and sizes, ensuring a snug fit and preventing slippage during lifting operations. Moreover, the human - centered design takes into account the comfort and safety of operators, making it easier to use in different work scenarios.

The practical benefits of using this hoist are substantial. Firstly, it dramatically shortens the operation time. In a well - known automotive manufacturing plant, after adopting this hoist, the time required to lift and position an engine was reduced by up to 30%. This not only speeds up the production process but also enables the plant to handle more orders within the same time frame.

Secondly, the hoist helps to lower the downtime rate. By providing a more reliable and efficient lifting solution, the frequency of equipment breakdowns and malfunctions is significantly reduced. In fact, some plants have reported a 25% decrease in unplanned downtime after integrating this hoist into their operations.

Another crucial advantage is the reduction in the risk of work - related injuries. The ergonomic design and secure clamping system mean that workers no longer have to strain themselves or rely on potentially unsafe manual lifting methods. As a result, the incidence of workplace accidents related to heavy - component handling has dropped by as much as 40% in some facilities, according to statistics.

Lastly, the hoist effectively lightens the burden on workers. With its lightweight structure and easy - to - operate features, workers can perform lifting tasks with less physical exertion, leading to improved job satisfaction and productivity.

The versatility of this automotive production line hoist is one of its most remarkable features. It can be used in a wide range of applications, including vehicle assembly, parts repair, warehousing and handling, assembly line optimization, and heavy machinery maintenance. Whether it's lifting a large engine during the assembly of a new car or moving a transmission for repair, this hoist proves to be an indispensable tool.

Don't just take our word for it. Here are some testimonials from our satisfied customers:

"Since we started using the automotive production line hoist, our workshop has become much more efficient. The adjustable clamping mechanism is a game - changer, allowing us to handle different parts with ease. We've seen a significant improvement in our overall productivity." - John, Manager of an Automotive Repair Shop

These positive reviews from real - world users further validate the effectiveness and reliability of our product.

In conclusion, the automotive production line hoist is not just a simple lifting tool; it is a strategic asset for modern automotive manufacturing and repair businesses. It offers a comprehensive solution to the industry's most pressing challenges, from improving efficiency to enhancing safety. If you are looking to transform your automotive production line and overcome the existing operational bottlenecks, don't hesitate to explore this amazing hoist further. Let your workshop bid farewell to the era of manual handling and embrace a more intelligent and safer future!