Efficient Application of Vertical Steel Coil Handling Equipment in Steel Rolling Mills

31 08,2025

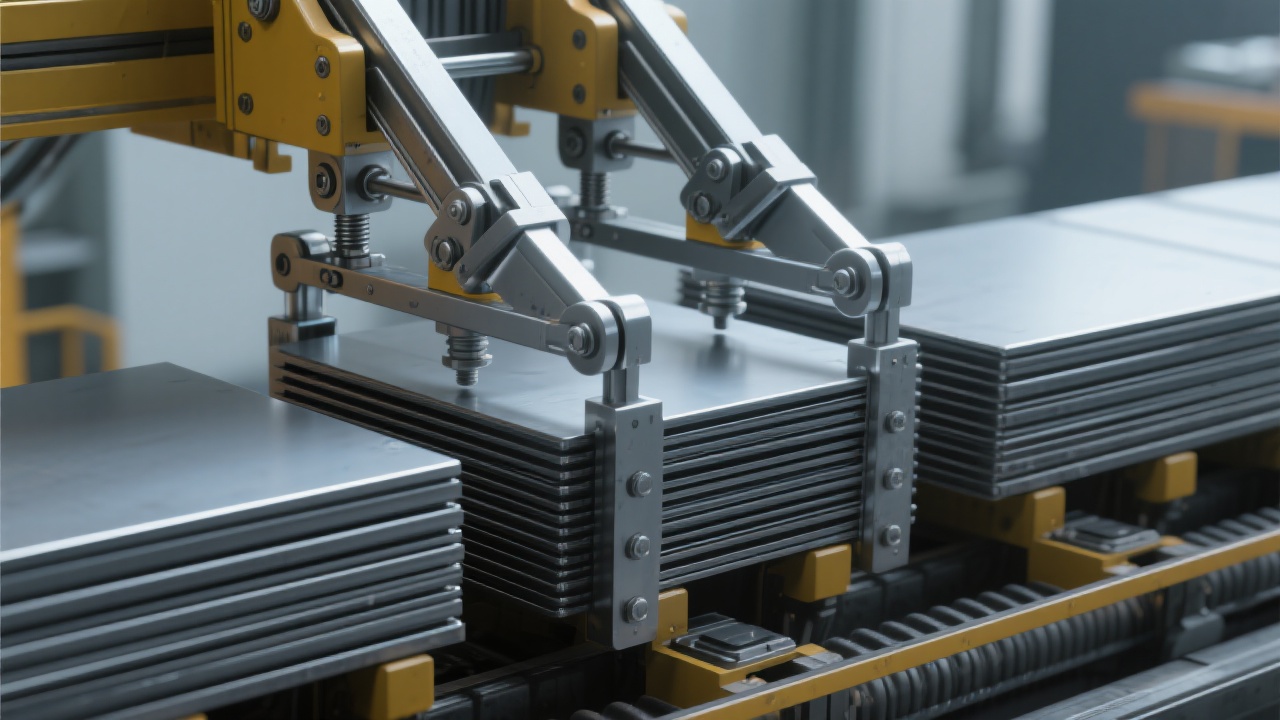

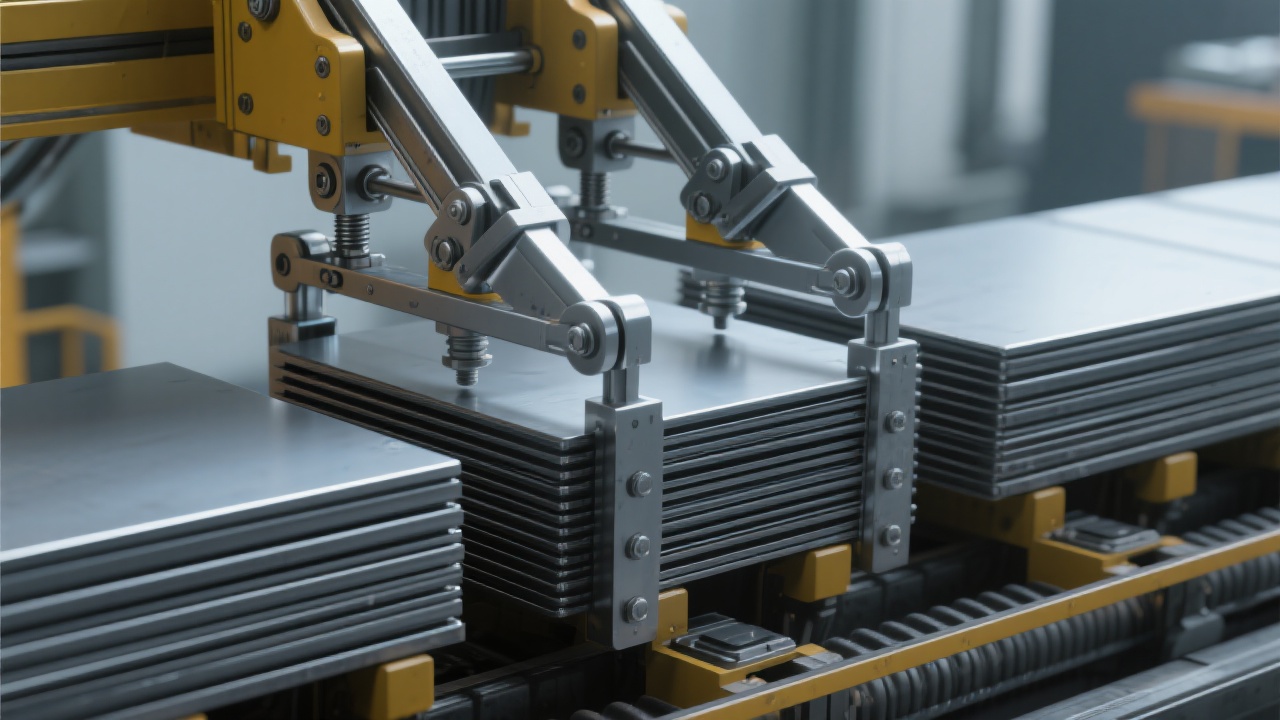

Industry Experience

Vertical steel coil handling equipment, specifically engineered for the vertical lifting and transportation of steel coils, combines high-strength materials, compact robust design, and a unique clamping mechanism to ensure operational safety and efficiency in steel rolling mills and various other industries. This article provides an in-depth analysis of its effective use within steel production lines, highlighting how it enhances productivity, reduces accident risks, and optimizes workflow. Through industry-specific application scenarios, comparative evaluations with similar market products, and real-world customer case studies, the equipment’s distinctive advantages and innovative features are emphasized, offering a reliable and safe steel coil handling solution worthy of industry adoption.

Efficient Vertical Coil Handling Equipment in Steel Rolling Mills: A Technical Insight

Vertical coil handling equipment has emerged as an indispensable asset within steel rolling mills, designed specifically to lift and transport steel coils with precision and safety. Crafted from high-strength materials, featuring compact robust structures and unique clamping mechanisms, these devices address the critical challenges encountered in coil handling operations across steel production lines.

Engineering Features Driving Performance and Safety

The core of vertical coil handling equipment lies in its meticulous design:

- High-Strength Materials: Utilizing alloy steels and reinforced composites, the lifting frame withstands dynamic loads exceeding 10 tons repeatedly, assuring durability in heavy-duty industrial environments.

- Compact & Robust Structure: The design optimizes space utilization on production floors while providing superior mechanical stability, reducing vibration and equipment wear during transport.

- Unique Clamping Mechanism: Engineered to securely grip vertical steel coils without surface damage, the clamping ensures stability in transit, minimizing slip risks that typically cause accidents and downtime.

Real-World Application in Steel Rolling Mills

Within steel rolling mills, the handling of steel coils presents unique operational challenges: heavy weight, bulkiness, and the need for swift movement along production sequences. The vertical coil handling equipment addresses these by enabling:

- Enhanced Throughput: Automated clamping and lifting reduce coil transfer time by approximately 25% compared to horizontal sling methods, driving up line efficiency.

- Improved Operator Safety: The secure locking system coupled with ergonomic controls reduces injury incidents related to coil slips by up to 40%, as documented by leading steel manufacturers.

- Process Optimization: Smooth, vibration-reduced transport lessens coil deformation risk, maintaining material integrity from processing to storage.

Multi-Industry Versatility: Beyond Steel Mills

Though tailored primarily for steel rolling mills, this equipment extends its value across diverse sectors:

| Industry |

Efficiency Gains |

Safety Improvements |

| Sheet Metal Processing Centers |

20% faster coil changeover times |

Reduced manual load handling by 50% |

| Warehousing & Logistics |

Streamlined vertical stacking and retrieval |

Minimized coil damage incidents by 30% |

| Ports & Shipping Yards |

Accelerated steel coil loading cycles by 18% |

Enhanced operator control with remote handling options |

Comparative Advantages Over Competitors

In a market saturated with coil lifting solutions, this vertical coil handling equipment stands out for several innovative aspects:

- Advanced Clamping Technology: Exclusive soft-grip liners reduce coil surface wear, outperforming typical rubber or metal clamps.

- Modular Design for Easy Maintenance: Quick-release parts facilitate up to 30% faster equipment servicing than industry averages.

- Integrated Safety Sensors: Real-time load monitoring alerts operators prior to overload conditions, elevating preventive safety protocols.

Solving Industry Pain Points with Practical Solutions

Steel mills frequently encounter specific challenges with coil handling, including accidental slippage, inefficient space use, and complex operator trainings.

The vertical coil handling equipment tackles these by providing:

- Slip Prevention: Its adaptive clamping adjusts to coil diameter variances, stabilizing loads reliably.

- Compact Footprint: Facilitates better storage planning, reducing coil handling aisles by 15%.

- User-Friendly Interface: Video-guided controls shorten operator training times by 25%, encouraging safer, confident handling.

How is your facility handling challenges related to steel coil transportation? What improvements could heighten your operational safety and throughput?

Discover tailored vertical coil handling solutions that transform your workflow