Efficient and safe container handling is the backbone of modern port logistics. With ever-increasing throughput demands, selecting the right container spreader becomes a critical factor for port operators, stevedores, and logistics companies aiming to maximize operational efficiency while minimizing risks.

Container dimensions and weights are standardized globally, but vary significantly between 20-foot, 40-foot, and specialized containers such as high-cube or refrigerated (reefer) units. For example, standard 20-foot containers typically weigh up to 2,300 kg empty, and can carry maximum gross weights of approximately 24,000 kg, while 40-foot containers may weigh up to 3,800 kg empty, with gross weights nearing 30,480 kg.

Selecting a spreader must start with accurately matching these key parameters:

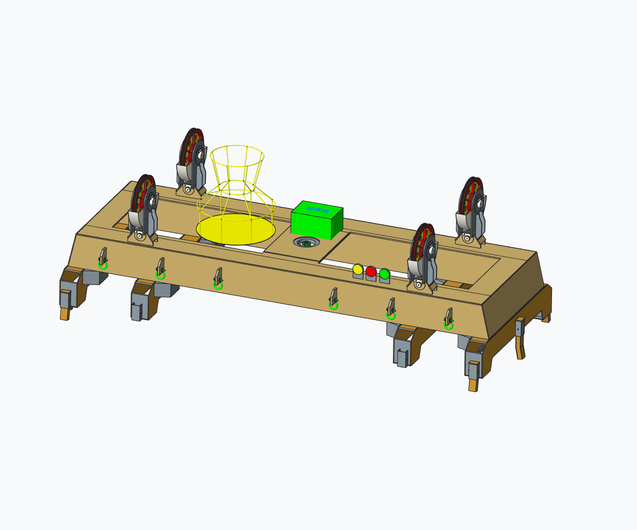

Taiding Heavy Industry has engineered container spreaders with features tailored to the rigors of global port environments:

| Feature | Description | Impact on Operations |

|---|---|---|

| Hydraulic Twistlock System | Enables fast and secure locking of containers of varying sizes | Reduces manual intervention & loading times by up to 20% |

| Telescopic Frame | Accommodates containers from 20’ to 45’ lengths | Increases operational flexibility at multi-container terminals |

| High-Strength Steel & Corrosion Resistance | Ensures durability in coastal and harsh environments | Lowers maintenance frequency & lifecycle costs by ~25% |

| Smart Monitoring Sensors | Real-time diagnostics for load and wear conditions | Improves safety and preempts failures, minimizing unplanned downtime |

In a pilot project at a major Northeast Asian port, Taiding’s spreaders have been deployed across dozens of quay cranes. Initial reports indicated a 15% increase in container throughput per crane shift, attributed to faster container locking cycles and reduced mechanical failures.

Additionally, these spreaders proved adaptable for handling both standard dry and specialized reefer containers without equipment changes, offering operational continuity during peak traffic periods.

Optimal spreader performance relies on rigorous, scheduled maintenance protocols. Taiding Heavy Industry provides customized maintenance packages, including:

Moreover, spreaders can be customized based on specific operational requirements such as lifting speeds, interface compatibility with various crane models, and remote-control capabilities for automation integration.

Global ports vary not only in physical infrastructure but also in regulatory and safety requirements. Taiding Heavy Industry’s approach involves continuous R&D investment, aligning spreader designs with international standards such as ISO 3874 and IEC specifications.

Their ongoing collaborations with worldwide port authorities and logistics operators ensure that product development anticipates future trends, including green port initiatives and automation readiness.