In the realm of steel coil handling, the steel coil horizontal lifting device emerges as a revolutionary solution, reshaping the efficiency and safety standards of multiple industries. This article delves into the design principles, core performance, and multi - industry applications of this cutting - edge device, providing valuable insights for enterprises in the export trade.

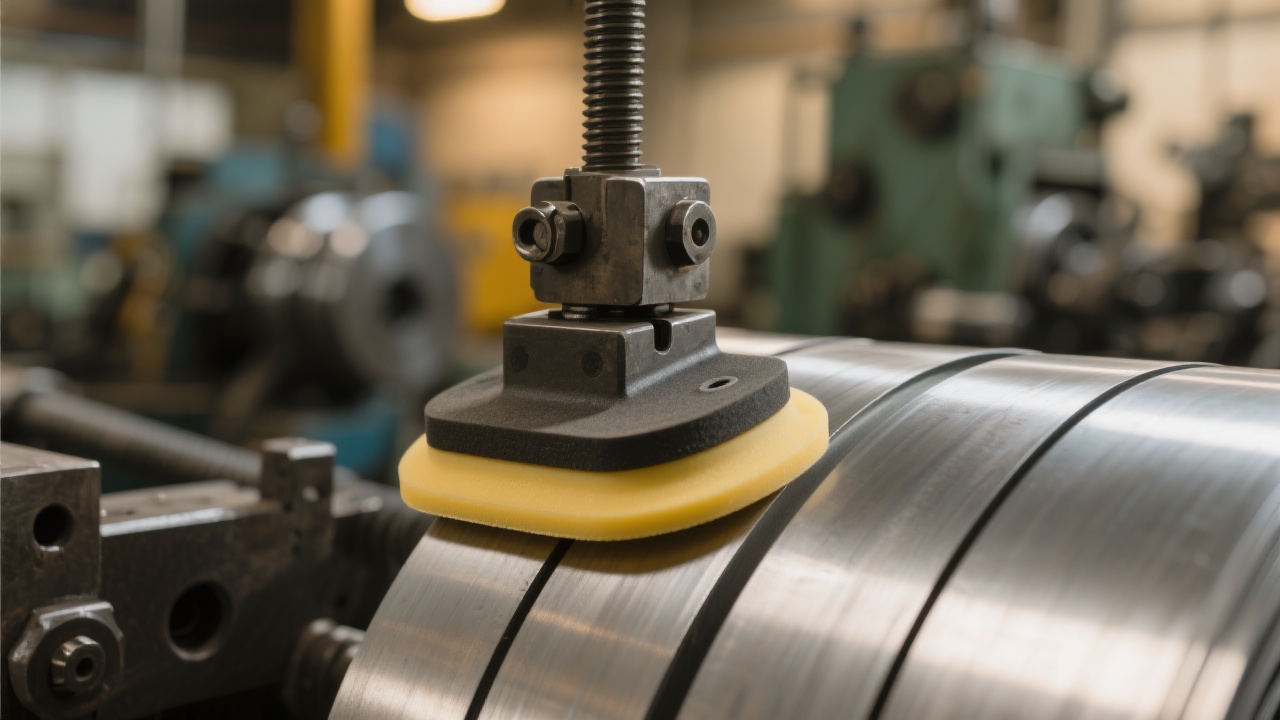

The steel coil horizontal lifting device features an innovative design and advanced grasping technology. Its unique structure allows it to adapt to steel coils of various sizes and weights. With a compact design, it can operate in limited spaces, which is a significant advantage compared to traditional bulky equipment. For instance, in a steel coil manufacturing factory, the device can easily handle coils ranging from 500 kg to 5 tons, thanks to its adjustable grasping mechanism. This adaptability not only saves space but also enhances the flexibility of operations.

To meet different operational requirements, the device offers multiple drive system options, including hydraulic, electric, and pneumatic drives. Hydraulic drives are known for their high power and stability, suitable for heavy - duty operations in steel mills and ports. Electric drives, on the other hand, are more energy - efficient and environmentally friendly, ideal for indoor operations in warehouses and processing centers. Pneumatic drives provide a cost - effective solution for light - to - medium - duty tasks. A customer from a钣金 processing center reported that after switching to an electric - driven steel coil horizontal lifting device, they reduced their energy consumption by 30% while maintaining the same level of productivity.

In steel coil manufacturing factories, the device significantly improves the efficiency of coil handling. Traditional methods often involve manual labor or less - efficient equipment, which are time - consuming and pose safety risks. The new device can lift and transport steel coils quickly and safely, reducing the handling time by up to 50%. For example, in a large - scale steel factory, the use of this device increased the daily output of steel coils by 20%.

Warehouses and ports deal with a large volume of steel coils. The steel coil horizontal lifting device simplifies the handling process, ensuring that coils can be stored and loaded/unloaded efficiently. In a major port, the adoption of this device reduced the waiting time for cargo handling by 40%, improving the overall logistics efficiency.

In heavy industries, safety is of utmost importance. The device's advanced safety features, such as anti - slip grasping and overload protection, ensure the safety of operators. A heavy - industry company reported that since using the device, the number of safety accidents related to steel coil handling has been reduced to zero.

When compared with traditional steel coil handling equipment, the steel coil horizontal lifting device stands out in terms of efficiency, safety, and cost - effectiveness. Traditional equipment is often large, complex, and requires more maintenance. In contrast, this new device has a simple structure, easy - to - operate controls, and lower maintenance costs. A customer survey showed that 80% of users preferred the new device over traditional ones due to its superior performance.

We understand that you may have some questions about the steel coil horizontal lifting device. Here are some common questions and answers:

| Question | Answer |

|---|---|

| Can the device handle non - standard steel coils? | Yes, its adjustable grasping mechanism allows it to handle non - standard steel coils within a certain range of sizes and weights. |

| What is the maintenance frequency of the device? | It depends on the usage. Generally, regular inspections are recommended every 3 - 6 months, and major maintenance is required once a year. |

If you have more questions, please feel free to leave a comment below, and we will answer them as soon as possible.

The steel coil horizontal lifting device is a game - changer in the field of steel coil handling. Its innovative design, flexible drive system, and multi - industry applications make it an essential tool for enterprises looking to optimize their material handling processes and enhance their competitiveness in the global market. Click here to learn more about how this device can transform your business!