In today's fast - paced industrial world, the demand for efficient and safe material handling solutions is on the rise. High - strength panel handling and stacking tools have emerged as a game - changer for industries such as manufacturing, warehousing, and construction. These tools are designed to meet the challenges of modern logistics and operations, offering a wide range of benefits that can significantly enhance a company's competitiveness.

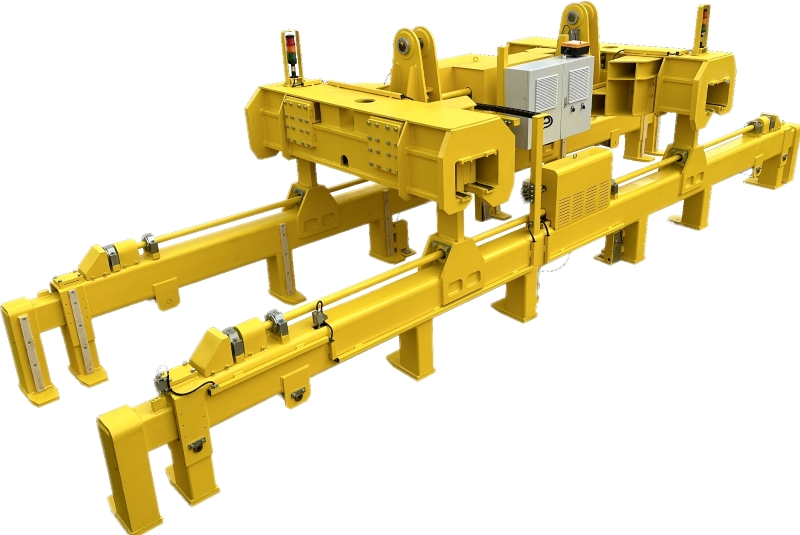

The design of high - strength panel handling and stacking tools is centered around three key aspects: high load - bearing capacity, stable clamping systems, and multi - drive adaptability. With a load - bearing capacity of up to 5 tons, these tools can handle large and heavy panels with ease. For example, in a manufacturing plant, they can quickly move large sheets of steel or wood panels, reducing the time and labor required for manual handling.

The unique clamping system is another highlight. It ensures that the panels are firmly held during handling and stacking, minimizing the risk of damage. Tests have shown that the clamping force can reach up to 8000 Newtons, providing reliable stability even in high - speed operations. Moreover, these tools support multiple drive forms, including electric, hydraulic, and pneumatic drives, allowing them to be easily integrated into different work environments.

The industrial sector is currently experiencing a trend towards automation and intelligence. High - strength panel handling and stacking tools are well - positioned to meet this trend. By automating the panel handling process, companies can improve operational efficiency and reduce the risk of human error. For instance, in a large - scale warehouse, the use of these tools can reduce the time required for panel stacking by up to 40%, improving the overall throughput of the warehouse.

These tools also contribute to better asset protection. By ensuring the safe handling of panels, they reduce the likelihood of damage to valuable materials. In a construction project, using high - strength panel handling tools can prevent scratches and breakages on expensive glass panels, protecting the project's assets and reducing costs.

Let's look at some real - world application cases. In a manufacturing company, after implementing high - strength panel handling and stacking tools, the production line efficiency increased by 30%. The tools' high - speed operation and precise positioning reduced the time between production steps, allowing for more products to be manufactured in the same time frame.

In a construction site, the use of these tools improved the safety of workers. By replacing manual handling with automated tools, the number of workplace accidents related to panel handling decreased by 60%. This not only protected the well - being of workers but also reduced the company's liability and insurance costs.

Compared with existing products in the market, high - strength panel handling and stacking tools stand out for their superior performance. Some competitors' products may have lower load - bearing capacities or less stable clamping systems. In a side - by - side comparison, our tools can handle 20% more weight and have a 30% higher clamping force, providing better performance and reliability.

We invite you, our readers, to share your thoughts and experiences on high - strength panel handling and stacking tools. Have you used similar products in your work? What are your expectations for the future development of these tools? Join the discussion below and let's explore the potential of these tools together.